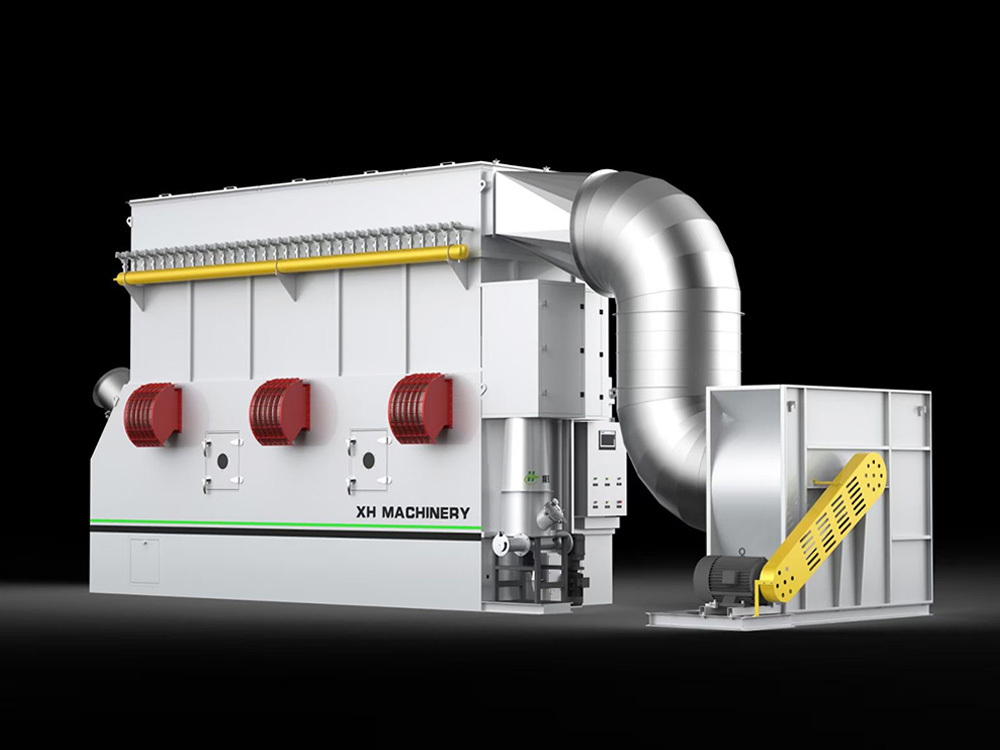

Compartment dust collector

Category:

Widely used in cement plant dust collection systems such as crushing, packaging, bin top, clinker cooler and various mills, it is also used in dust collection of waste gas from metallurgy, chemical industry, machinery and civil boilers.

Advantages

Modular bolted connection, no welding required, can be assembled on site, easy to transport, simple installation suitable for small spaces and installation inside high-rise buildings. The inner and outer surfaces of the box are phosphated and high-pressure electrostatic sprayed, with strong anti-corrosion ability and durability. The inlet and outlet ports, inspection ladders and ash discharge direction are multi-adjustable, which facilitates system design and on-site installation. When the filtration area is greater than 100 square meters, a screw conveyor + ash discharge valve can be used for the dust collector hopper. The ash discharge valve of the dust collector hopper is standard, and level gauge, fire sprinkler, explosion-proof pressure relief device and hopper heating and insulation can be optionally selected.

●Standard Configuration ○Optional Configuration

| Product Model | XH/V32-3 | XH/W32-4 | XH/W32-5 | XH/W32-6 | XH/W64-4 | XH/N64-5 | XH/W64-6 | XH/W64-7 | XH/W64-8 |

| Air Handling Volume (㎡/h) | 6000 | 7500 | 10000 | 12000 | 16000 | 20000 | 24000 | 28000 | 31000 |

| Filtration Air Velocity (m/min) | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Filter Material Specifications | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 | φ130*2500 |

| Total Filtration Area (㎡) | 96 | 128 | 160 | 192 | 256 | 320 | 384 | 448 | 512 |

| Net Filtration Area (㎡) | 64 | 96 | 128 | 160 | 192 | 256 | 320 | 384 | 458 |

| Number of Dust Collector Rows | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Number of Dust Collector Chambers | 3 | 4 | 5 | 6 | 4 | 5 | 6 | 7 | 8 |

| Number of Filter Bags per Chamber | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 |

| Total Number of Filter Bags | 96 | 128 | 160 | 192 | 256 | 320 | 384 | 448 | 512 |

| Dust Collector Resistance (pa) | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 | 1200~1500 |

| Dust Collection Method | Hopper Dust Collection | Hopper Dust Collection | Hopper Dust Collection | Hopper Dust Collection | Hopper Dust Collection | Hopper Dust Collection | Hopper Dust Collection | Hopper Dust Collection | Hopper Dust Collection |

| Matching Motor (kw) | 11kw | 15kw | 18.5kw | 22kw | 30kw | 40kw | 45kw | 55kw | 55kw |

| Inlet Gas Dust Concentration (g/N㎡) | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 |

| Outlet Gas Dust Concentration (mg/N㎡) | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 |

| Dust Removal Efficiency (%) | 99.99% | 99.99% | 99.99% | 99.99% | 99.99% | 99.99% | 99.99% | 99.99% | 99.99% |

| Air Leakage Rate (%) | 2% | 2% | 2% | 2% | 2% | 2% | 2% | 2% | 2% |

| Applicable Temperature | ≤180℃ | ≤80℃ | ≤80℃ | ≤80℃ | ≤80℃ | ≤80℃ | ≤80℃ | ≤80℃ | ≤80℃ |

| Total Equipment Weight (kg) | 3000 | 3750 | 5000 | 6000 | 7500 | 9000 | 11000 | 13000 | 14500 |

| Screw Conveyor | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Pneumatic Conveying | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Vibration Motor | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Differential Pressure Transmitter | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Temperature Transmitter | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Fire Sprinkler | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Level Gauge | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Explosion Relief Device | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Audible and Visual Alarm | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

Keyword:

Compartment dust collector

Previous:

Next:

Creating exclusive green solutions for various industries

With rich construction and installation experience, we provide comprehensive and full-process services for dust removal projects, including planning, investigation, design, procurement, equipment sets, non-standard equipment research and development, etc., ensuring copy

Get Your Exclusive Solution

Our staff will contact you within 24 hours (working days).