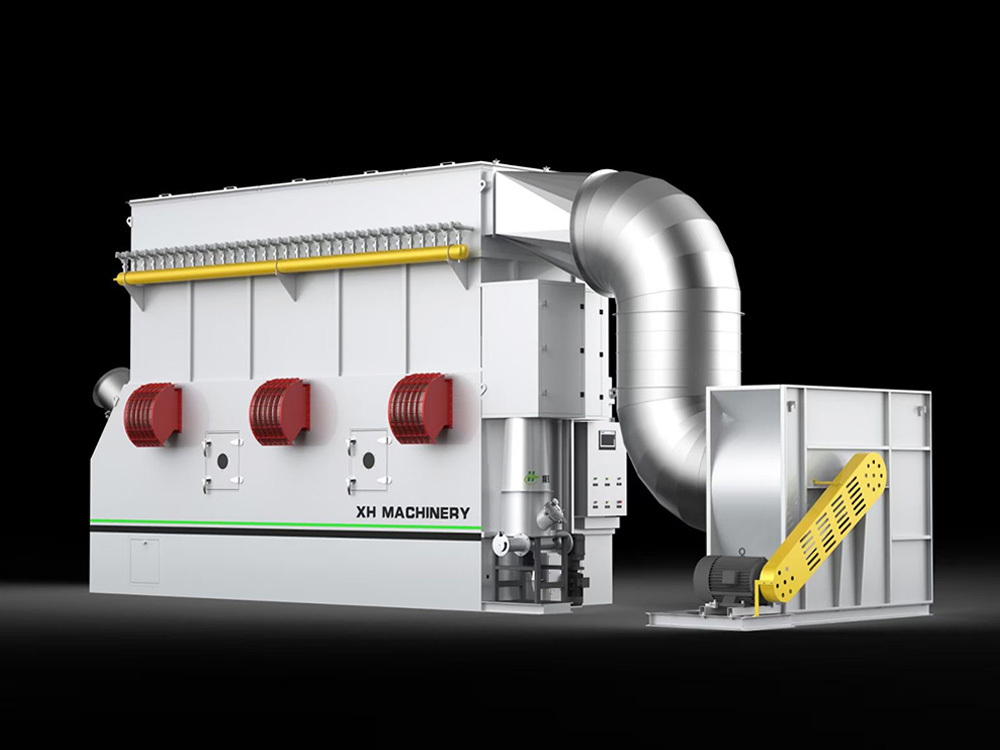

Energy-saving pulse bag filter

Category:

Energy-saving pulse dust collectors are widely used in various industrial fields, including power, steel, cement, metallurgy, chemical, building materials, and food processing. Their technological advantages mainly lie in high dust removal efficiency, low energy consumption, stable operation, easy maintenance, intelligent control, and environmental benefits.

Technical Parameters

| Required Air Volume | Rated 53386 | Rated 45000 | Rated 45000 | Rated 45000 | Remarks | ||

| 1 | Requirements | I-shaped diapers (export equipment) | Mattress (export equipment) | Sanitary napkins (export equipment) | 1-meter mattress (export equipment) | ||

| 2 | Design Air Volume | Magnification factor of 1.3 | 70000m³/h | 60000m³/h | 60000m³/h | 60000m³/h | Customizable, air volume up to 80000m³/h |

| 3 | Filter Area | 474㎡ | 397㎡ | 397㎡ | 397㎡ | ||

| 4 | Dust Discharge Method | Pressurized Block Extrusion | Mechanical Pressing | Mechanical Pressing | Mechanical Pressing | Mechanical Pressing | |

| 5 | Filter Bag Size | Anti-static, waterproof, high-temperature resistant, usable for more than 2.5 years | 130*2700mm | 130*2500mm | 130*2500mm | 130*2500mm | |

| 6 | Number of Filter Bags | No holes should be created during the jet pulse cleaning. | 420 | 360 | 360 | 360 | |

| 7 | Cage Size | Sturdy and durable, no deformation | 129*2700mm | 129*2500mm | 129*2500mm | 129*2500mm | |

| 8 | Number of Cages | 420 | 360 | 360 | 360 | ||

| 9 | Gap between filter bags | ≥5cm | 5cm | 5cm | 5cm | 5cm | |

| 10 | Jet Pulse Cleaning Method | Central and gap jet pulse cleaning | Double jet pulse cleaning | Double jet pulse cleaning | Double jet pulse cleaning | Double jet pulse cleaning | |

| 11 | Pulse Valve Model | DMF-Z-40S | DMF-Z-40S | DMF-Z-40S | DMF-Z-40S | ||

| 12 | Number of Pulse Valves | 69+4 (inner slope jet pulse cleaning) | 59+4 (inner slope jet pulse cleaning) | 59+4 (inner slope jet pulse cleaning) | 59+4 (inner slope jet pulse cleaning) | ||

| 13 | Control Cabinet Operation Mode | PLC plus touch screen | Huichuan brand PLC and screen, Plus remote control module | Huichuan brand PLC and screen, Plus remote control module | Huichuan brand PLC and screen, Plus remote control module | Huichuan brand PLC and screen, Plus remote control module | |

| 14 | Low-voltage electrical components | Schneider Electric | Schneider Electric | Schneider Electric | Schneider Electric | ||

| 15 | Plate thickness | 6 mm | 6mm | 6mm | 6mm | 6mm | |

| 16 | Surrounding plate thickness | 5 mm | 5mm | 5mm | 5mm | 5mm | |

| 17 | Ground frame angle iron | 6 mm | 6mm | 6mm | 6mm | 6mm | |

| 18 | Dust Removal Method | Online real-time non-stop dust removal | Pneumatic conveying, online dust removal | Pneumatic conveying, online dust removal | Pneumatic conveying, online dust removal | Pneumatic conveying, online dust removal | |

| 19 | Duct Interface | 550: 2, 350: 3 | 500: 2, 300: 1 | 500: 1, 300: 1 | 500: 1, 300: 1 | ||

| 20 | Air Valve | No leakage required | Pneumatic air valve | Pneumatic air valve | Pneumatic air valve | Pneumatic air valve | |

| 21 | Spark Detection | Yes | XHSF-05 (10 probes) | XHSF-03 (6 probes) | XHSF-02 (4 probes) | XHSF-02 (4 probes) | |

| 22 | Pipeline Fire Suppression | Yes | 5 sets of double-spray fire suppression devices | 3 sets of double-spray fire suppression devices | 2 sets of double-spray fire suppression devices | 2 sets of double-spray fire suppression devices | |

| 23 | Explosion-proof Valve Model and Quantity | 5 | DN550: 2 DN350: 3 | DN500: 2 DN300: 1 | DN500: 1 DN300: 1 | DN500: 1 DN300: 1 | |

| 24 | Explosion Vent | Flameless, model 410*480 | 4 flameless explosion vent devices | 3 flameless explosion vent devices | 3 flameless explosion vent devices | 3 flameless explosion vent devices | |

| 25 | Fire Suppression Method | Automatic pneumatic fire suppression when four points inside the box simultaneously exceed the temperature limit; manual fire suppression is also possible. | Internal spraying device for dust removal equipment, manual and automatic, with interlocking alarm | Internal spraying device for dust removal equipment, manual and automatic, with interlocking alarm | Internal spraying device for dust removal equipment, manual and automatic, with interlocking alarm | Internal spraying device for dust removal equipment, manual and automatic, with interlocking alarm | |

| 26 | Total Power | 8.5KW | 8.45KW | 8.45KW | 8.45KW | 8.45KW | |

| 27 | Filtration Efficiency | ≥99% | ≥99.6% | ≥99.6% | ≥99.6% | ≥99.6% | |

| 28 | Equipment Warranty | 2 years | 2 years | 2 years | 2 years | 2 years | |

Technical Advantages

• High dust removal efficiency:

High dust removal efficiency, generally reaching over 99%, capable of capturing fine dust particles larger than 0.3 microns.

Outlet dust concentration can be controlled at an extremely low level, far below national emission standards.

• Low energy consumption:

Utilizing pulse jet cleaning technology, the pulse valve operates instantaneously, with energy consumption only 30%~50% of traditional cleaning methods.

The system's main motor has low power, using differential pressure control for cleaning operation, requiring low energy.

• Stable operation:

Stable performance; changes in operating conditions such as processing air volume, gas dust content, and temperature have little impact on dust removal effectiveness.

Stable equipment resistance, high filter bag regeneration efficiency, and thorough cleaning without dead zones.

• Easy maintenance:

Convenient filter bag replacement, using an elastic ring design for easy installation and removal.

Modular design supports maintenance without shutdown, reducing downtime.

Long filter bag lifespan, uniform cleaning reduces mechanical wear, and the service life can be extended to 1~3 years.

• Intelligent control:

Equipped with a PLC control system or dedicated program controller to achieve automated control and remote monitoring.

Can automatically adjust the cleaning frequency and intensity according to actual needs, minimizing energy consumption.

Provides fault alarm function to promptly identify and resolve issues, ensuring smooth production.

• Environmental benefits:

Dust from the cleaning process falls directly into the hopper, with no risk of leakage, avoiding secondary pollution.

Collected dust is easily recyclable, meeting the requirements of green production.

Suitable for various operating conditions, such as high temperature, low temperature, humidity, and dryness, with a wide range of applications

Keyword:

Energy-saving pulse bag filter

Previous:

Next:

Creating exclusive green solutions for various industries

With rich construction and installation experience, we provide comprehensive and full-process services for dust removal projects, including planning, investigation, design, procurement, equipment sets, non-standard equipment research and development, etc., ensuring copy

Get Your Exclusive Solution

Our staff will contact you within 24 hours (working days).