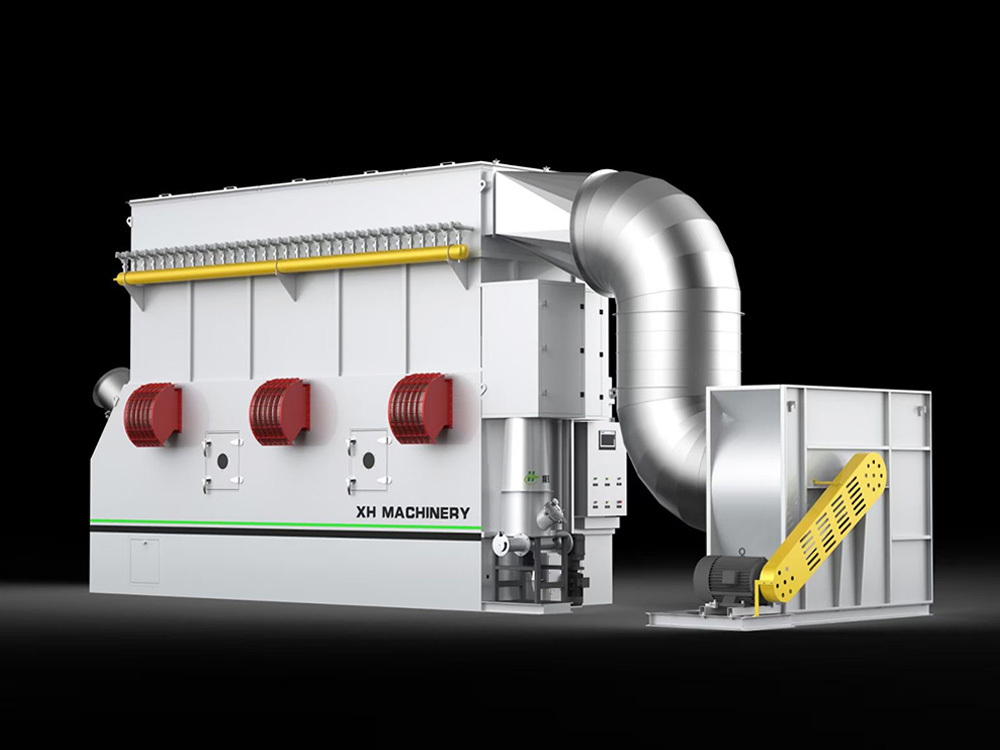

Cartridge dust collector

Category:

Widely used in cement, steel, power, food, metallurgy, chemical and other industrial fields, it is the best solution to solve the problems of traditional dust collectors, such as difficulty in collecting ultrafine dust, high filtration wind speed, poor ash removal effect, easy wear and tear of filter bags, and high operating costs. Compared with various bag-type and electrostatic precipitators on the market, it has the advantages of large effective filtration area, low pressure drop, low emission, small size, and long service life.

Advantages

It has the advantages of small size, high efficiency, low investment, and easy maintenance.

●Standard Configuration ○Optional Configuration

| Product Model | XH-2 | XH-4 | XH-8 | XH-6 | XH-8 | XH-10 | XH-12 | XH-14 | XH-10 | XH-18 | XH-20 | |

| Air volume (m 3 /h) | 2042 | 4085 | 8170 | 12254 | 16339 | 24768 | 29722 | 34675 | 39629 | 44582 | 49536 | |

| Filtration area (m 2) | 34.04 | 68.08 | 136.16 | 204.24 | 272.32 | 412.8 | 495.36 | 577.92 | 660.48 | 743.04 | 825.6 | |

| Number of filter cartridges | 4 | 8 | 16 | 24 | 32 | 40 | 48 | 56 | 64 | 72 | 80 | |

| Number of pulse valves | 2 | 4 | 8 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Pulse valve specifications | 1.5 | 1.5 | 1.5 | 1.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | |

| Mobile ash hopper | 1 | 1 | 2 | 3 | 3 | 4 | 4 | 6 | 8 | 8 | 10 | |

| Filter cartridge specifications (mm) | φ320*660 | φ320*660 | φ320*660 | φ320*660 | φ320*660 | φ320*800 | φ320*800 | φ320*800 | φ320*800 | φ320*800 | φ320*800 | |

| Equipment resistance (Pa) | <800 | <800 | <1000 | <1200 | <1200 | <1200 | <1200 | <1200 | <1200 | <1200 | <1200 | |

| Dust removal efficiency (%) | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | 100.9 | 101.9 | 102.9 | 103.9 | 104.9 | 105.9 | |

| Inlet dust concentration (g/m 3) | <30 | <30 | <30 | <30 | <30 | <30 | <30 | <30 | <30 | <30 | <30 | |

| Outlet dust concentration (mg/m 3) | <10 | <10 | <10 | <10 | <10 | <10 | <10 | <10 | <10 | <10 | <10 | |

| Air consumption (m 3 /min) | 0.3 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.7 | 0.7 | 0.7 | |

| Fan | Model | B4-72No3.6A | B4-72No4A | B4-72No4A | B4-72No-4.5A | B4-72No5A | B4-72-6C | B4-72-10C | B4-72-10C | B4-72-12C | B4-72-12C | B4-72-12D |

| Motor power (kW) | Y160L-2(3KW) | Y132S1-2(5.5kw) | Y132S1-2(5.5kw) | Y132S2-2(7.5kw) | Y160M2-2(15kw) | Y160L-4(15KW) | Y180M-4(18.5KW) | Y180M-4(18.5KW) | Y200L1-6(18.5KW) | Y225M-6(30KW) | Y280S-6(45KW) | |

| Ash discharge valve | Ash discharge valve dimensions (mm) | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 |

| Ash discharge valve | Gearbox model | BLD1-29-0.55 | BLD1-29-0.55 | BLD1-29-0.55 | BLD1-29-0.55 | BLD1-29-0.55 | BLD1-29-0.55 | BLD1-29-0.55 | BLD1-29-0.55 | BLD1-29-0.55 | BLD1-29-0.55 | BLD1-29-0.55 |

| Ash discharge valve | Speed (r/min) | 48 | 48 | 48 | 48 | 48 | 49 | 50 | 51 | 52 | 53 | 54 |

| Ash discharge valve | Motor power (kW) | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 1.6 | 2.6 | 3.6 | 4.6 | 5.6 | 6.6 |

| Operating temperature (°C) | <130 instantaneous 150℃ | <130 instantaneous 150℃ | <130 instantaneous 150℃ | <130 instantaneous 150℃ | <130 instantaneous 150℃ | <130 instantaneous 151℃ | <130 instantaneous 151℃ | <130 instantaneous 151℃ | <130 instantaneous 151℃ | <130 instantaneous 151℃ | <130 instantaneous 151℃ | |

| Screw conveyor | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| Differential pressure transmitter | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| Temperature transmitter | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| Fire sprinkler | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| Level meter | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| Explosion relief device | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| Audible and visual alarm | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| Dimensions (L*W*H) (mm) | 800*2200*3320 | 1000*2200*3320 | 2000*2200*3320 | 2000*2200*3790 | 3000*2200*3790 | 6060*2300*4080 | 7070*2300*4080 | 8080*2300*4080 | 6060*2300*4080 | 7070*2300*4080 | 8080*2300*4080 | |

Keyword:

Cartridge dust collector

Previous:

Next:

Creating exclusive green solutions for various industries

With rich construction and installation experience, we provide comprehensive and full-process services for dust removal projects, including planning, investigation, design, procurement, equipment sets, non-standard equipment research and development, etc., ensuring copy

Get Your Exclusive Solution

Our staff will contact you within 24 hours (working days).